Frequently Asked Questions

- HOME

- FAQ

About Filter

What are the meanings of “micron” and “mesh” for filtration?

What are the features and differences of each filtration material?

What is filter pressure drop?

What is notch wire?

How can we replace filter elements?

How can we clean filter elements?

Can we replace a visual type indicator to an electric contact indicator?

What is the indicator connection procedure?

What are high-pressure elements?

What is product weight?

How can we handle if there is oil leakage from the filter?

・ Any defect such as cracks on any of the product?

・ Is the tightening torque for each part correct?

・ No defect or degradation of sealing parts (O-ring, packing)?

If the above confirmation does not help to figure it out, please ask us.

What are the working temperatures of filters?

What are the max working pressures of filters?

Circuit peak pressure of pressure fluctuation should be under the max working pressure.

What are the structures of element?

Is it OK to install the filter sideways?

Is it OK to install the filter upside down?

Which fluids are applicable?

Is there a filter for water?

Is it OK to replace the element to the one with different filtration rating?

■If select finer filtration rating: Service life of the element tends to shorten since it removes more contaminants.

■If select rougher filtration rating: there is a possibility of damage to the equipment since it removes larger contaminants.

Is it OK to change flow direction of the filter?

■UL, UM, UH Filters

Opposite flow direction is available for UL, UM, UH filters by reversing the cover 180°.

*Be sure that arrow mark of flow direction on the cover is correct.

What is material of filter element?

Why does indicator activate immediately even replacing to the new element?

Main causes might be followings:

■The element is clogged.

The most common cause is clogging. Especially if using finer element such as 3C and 8C, contaminants on its surface can’t be detected visually. Even if using with new oil, there can be contaminants depends on new oil condition and how it is refilled, that might cause clogging.

■High oil viscosity

If ambient temperature is low at startup for example, high viscosity may activate indicator. In this case, indicator will be restored by continuous operation.

■Using different element from the previous model

If newly installed element is finer than the previous one, clogging might occur immediately.

What will happen if installing the cover of UL, UM, UH filters in the opposite direction of the arrow mark of flow direction?

*Be sure that arrow mark of flow direction on the cover is correct.

About Heat Exchanger

Is it OK to reverse inlet/outlet of shell and tube type heat exchanger?

■Shell side

・Reversible for 2 passes and 4 passes heat exchanger

・Not available for 1 pass heat exchanger due to performance reduction

■Tube side

・To prevent performance reduction due to air pocket inside of heat exchanger, flow direction should be from the lower side to the upper side for standard. If this performance reduction is small enough to disregard, reverse flow direction is available.

・Reverse flow direction is not available for 1 pass heat exchanger.

Is it OK to reverse inlet/outlet of air-cooled type heat exchangers?

What is the current value for air-cooled heat exchangers?

Is there any performance data of heat exchangers?

If operating condition is quite different with the specific, please ask us.

What is heat transfer area for the heat exchangers?

What are structures of heat exchangers

Is it OK to install the heat exchanger vertically?

Is it OK to install the heat exchanger upside down?

What are the max working temperatures for heat exchangers?

■Shell side: 90℃

■Tube side: 60℃

Please ask us about special specs for higher temperatures.

About the fine bubble generator

Please tell us about the cleaning effect

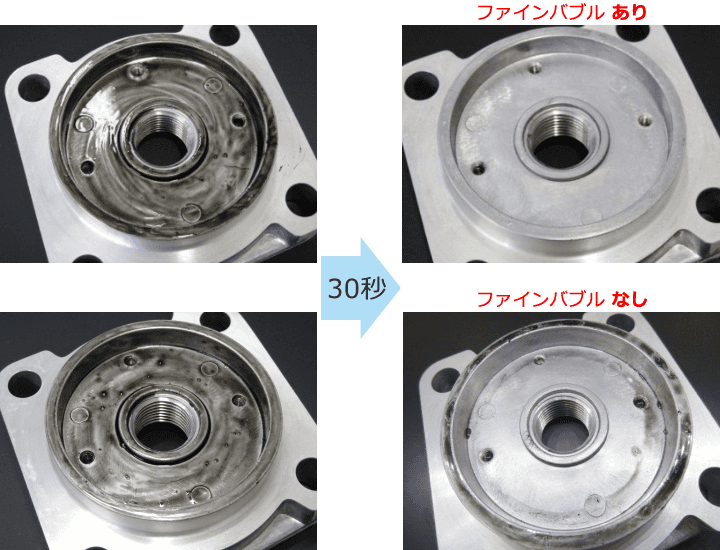

Fine bubble cleaning experiment video by HELIX NOZZLE

Cleaning conditions

- Nozzle:

- HELIX NOZZLE [TH-05]

- Cleaning method:

- Underwater cleaning

- Water temperature:

- 50 ℃

- Water pressure:

- 0.24MPa

- Contamination:

- Hydraulic oil VG46

Fine bubble cleaning with HELIX NOZZLE is especially effective against oil stains.

Cleaning conditions

- Nozzle:

- HELIX NOZZLE [TH-05]

- Cleaning method:

- Underwater cleaning

- Water temperature:

- 40 ℃

- Water pressure:

- 0.2MPa

- Cleaning time:

- 30 seconds

- Washed items:

- Aluminum die-cast

- Contamination:

- Hydraulic oil VG46

What are the usages?

Fine bubble is expected to be effective in various fields.

Industry

- Cleaning

- Wastewater treatment

- Precision peeling

Agriculture

- Agricultural water

- Hydroponics

- Plant factory

Fishery

- Aquaculture

- Maintain freshness

Food and drink

- Vegetable washing

- Sterilization, disinfection

- Hydrogen water production

Environment

- Water purification

- Wastewater treatment

- Oil-water separation

Pets

- Pet bath

- Pet shower

Beauty /Health

- Shower head

- Hot spring

- Cosmetics

Others

- Medical, pharmaceuticals

- Chemical synthesis

- Ships, etc.

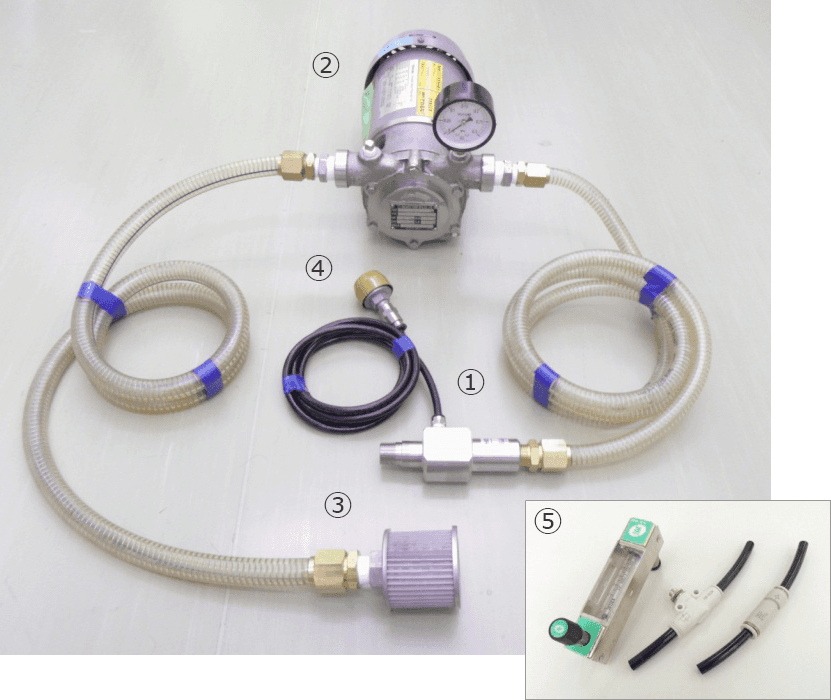

Please tell me how to use

Example of fine bubble generator

- ① HELIX NOZZLE [TH-03]

-

② Hydraulic pump

100V 0.1kw -

③ Suction filter

Prevents foreign matter from entering the pump. -

④ Air breather, air filter

Prevents foreign matter from entering the nozzle intake side. -

⑤ Intake control type

The self-priming amount can be adjusted with the adjustment valve and flow meter.

Note) Please install the nozzle underwater or in-line for use.

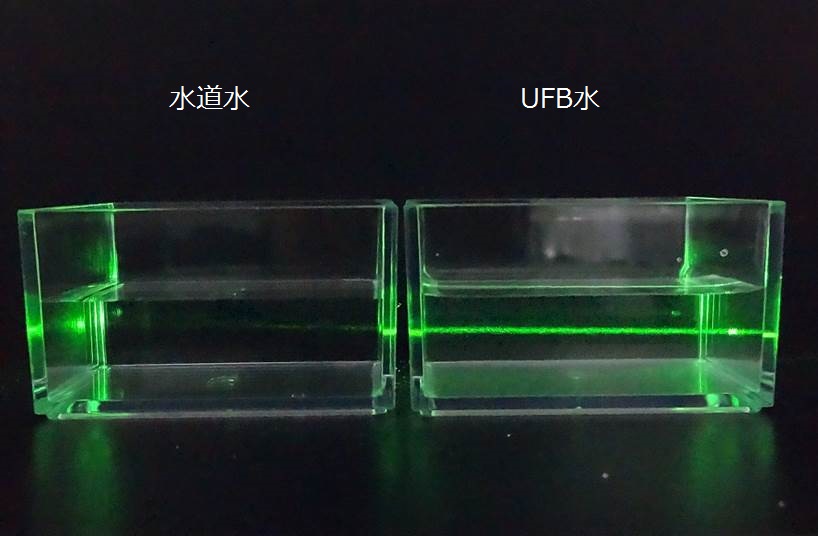

Is it possible to generate an ultra fine bubble with HELIX NOZZLE?

Is possible. HELIX NOZZLE can generate various bubbles such as ultra fine bubbles (nano bubbles), micro bubbles,

and milli bubbles.

In addition, it is possible to adjust the generation distribution by adjusting the amount of intake air.

An example of irradiating the ultrafine bubble water (right side) generated by HELIX NOZZLE with a laser.

UFB has the property of being difficult to surface and has been confirmed to stay in water for a long time

(several months).

About Oil-Water Separator

How long is the life of the filter element?

Can I buy only the element?

Can the element be reused by backwashing?

Backwashing reduces the hydrophilic and oil-repellent function and affects the processing accuracy, so it cannot be done.

What is the chemical resistance?

Due to the material of the filter unit and filter element, it is not recommended to use it in a treatment liquid containing alcohol or a strong alkali treatment liquid. Please contact us for details.

Is it possible to separate even if the treatment liquid contains impurities or metal powder?

Separable. However, it is recommended to install a pre-filter because impurities and metal powder may adhere to the filter element and cause clogging.

Is the oil in the emulsion state separable?

Emulsion containing surfactant is difficult to process, but it may be separable depending on the emulsified state. Please contact us for details.

What kind of application can the oil-water separation filter unit be used for?

Is it possible to process 100ℓ /min or more?

We design and manufacture according to the amount of processing of our customers. Please contact us first.

Why is it necessary to reduce the oil concentration of wastewater to 5ppm or less?

The Water Pollution Control Law stipulates that the oil concentration of wastewater should be 5 ppm or less.

The wastewater standards in the Water Pollution Control Law and Sewerage Law include harmful substances and non-hazardous substances. For example, the content of normal hexane extract (normal hexane value) is 5 ppm for mineral oil and 30 ppm or less for animal and vegetable oil. Has been done.

How much should you imagine that the oil concentration should be 5ppm or less?

The oil concentration of 5ppm or less is the level of a cap full of water in 5 drums.

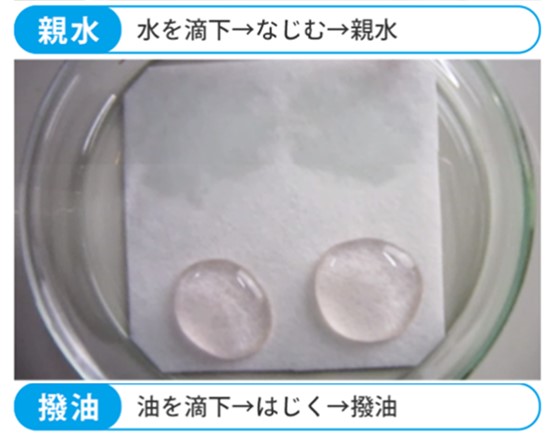

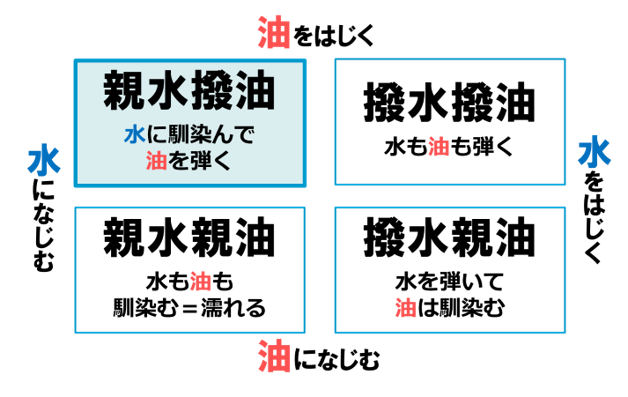

What is the hydrophilic oil repellent used in filter paper?

Hydrophilicity is to become familiar with water.

Oil repellent is the repelling of oily liquids. Hydrophilic oil repellency is the repelling of

oily liquids, although it is compatible with water.

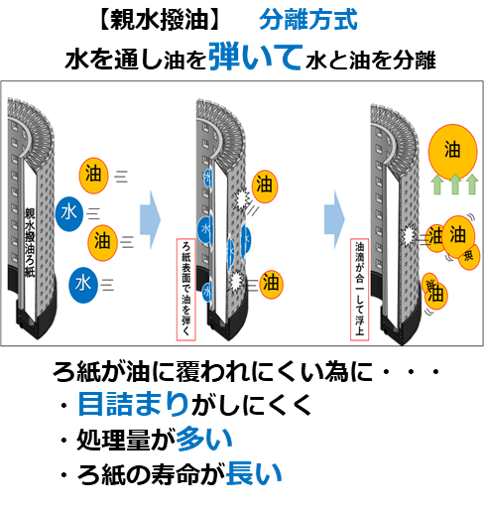

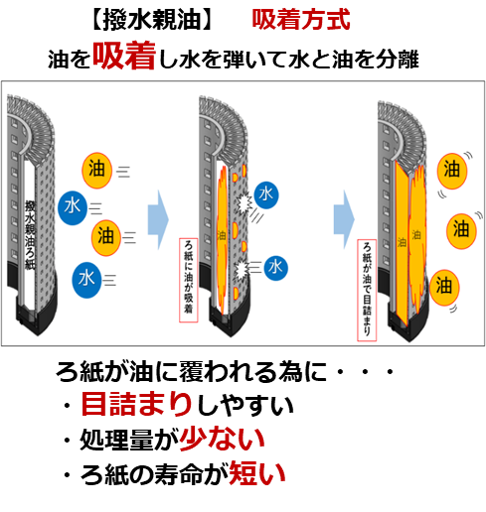

What are the advantages of using hydrophilic oil repellent for filter elements?

For conventional oil-water separation filters, the adsorption method has been widely used (right figure), but to take advantage of the hydrophilic oil-repellent performance and repel oil to separate oil-water (left figure), the filter paper becomes oil. There are various merits such as being hard to be covered and clogging.

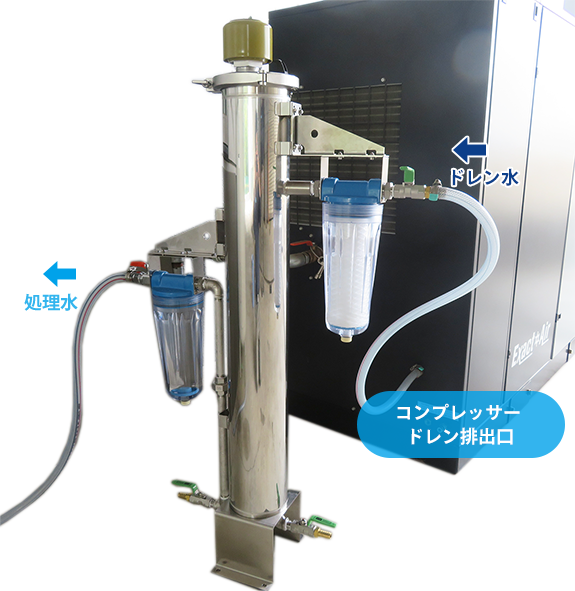

What is drain water?

Why is it necessary to install a drain separator?

Because the oil concentration of drain water is high, if it is drained as it is, it will cause environmental pollution and violate the law. Therefore, it is necessary to remove the oil with a drain separator to reduce the oil concentration of the factory wastewater to 5 ppm or less.

Please tell me how to replace the element of the drain separator.

1. Preparation

Prepare a new filter element /O-ring.

Turn the valves at the bottom of the drain separator in the order of ① and ② to drain the treated water and drain

water from the maintenance outlet.

2. Disassembly

Loosen the clamp on the top of the main unit, remove the lid, grasp the cross handle inside, and slowly pull out

the element holder.

3. Element removal

Remove the element from the element holder.

4. Element mounting

Attach the O-ring to the new element. Then attach the element to the element holder.

5. Insert element holder

Insert the element holder into the main body.

6. Attaching the main body lid

Close the lid of the main body and tighten the clamp.

Does the drain separator for the compressor need any power supply?

It has a structure that can withstand the pressure of drain water discharged from the compressor, and does not require a power supply or power because it does not require a device to control the pressure.

What is the meaning of WTT in the WTT Division?

About Purchase

How can we order products?

Please contact with a distributor/dealer supporting your country ONLY. Please do not send your inquiry to any others to avoid duplications. In addition, please clarify (1) END USER, (2) FINAL DESTINATION (COUNTRY), and (3) APPLICATION when requesting to our distributors. Unless it is clarified, we are unable to answer for security trade control reason.

Are products in stock?

What is delivery of products?

What is the price of products?

How can we find the distributor?

How can we find the drawings?

Please ask our distributor for special items.

How can we find the drawing data?

Please ask our distributor for special items.

Where can we find the catalog?

Please ask our distributor for catalog booklet.

Are custom-made items available other than standard item in the catalog?

Can you select appropriate product for us?

Are there compatible filter elements for discontinued ones?

| Filtration rating code | |||

|---|---|---|---|

| Former/Discontinued | 3M | 6M | 10M |

| Current/Compatible | 3C | 8C | 8C |

How can we find compatible products for discontinued ones?

Can we purchase discontinued filter elements?

Can we purchase discontinued indicators?

Contact

-

TEL

+81-3-6912-9922+81-3-6912-9922

Excluding Saturdays, Sundays and Holidays -

Inquiry & Request